High Quality, Higher Standards

Stainless Foundry & Engineering Quality Department conducts quality inspections for each casting. We are prepared to meet or exceed the growing needs of the ever-evolving business practices needed for stainless foundries. Our prevention and inspection systems are designed to be beneficial for every facet of our business (customer, suppliers, foundry, machining, and assembly).

Quality Assurance management administers and implements the quality program and its systems.

The Director of Quality performs the following:

- Identities quality problems through quality inspections

- Initiates, recommends or provides solutions to quality problems through designated channels

- Verifies implementation of solutions

- Assures that further processing, delivery, installation, or use is controlled until proper disposition of a nonconformance, deficiency, or unsatisfactory condition has occurred.

Quality Management Overview

Our quality management department is broken down into 4 sections:

- Quality inspections & testing verifications

- Voice of the customer – assistance and corrective & preventive actions

- Auditing and systems development & maintenance

- Certification verification & completion

Our quality management systems are built to maintain compliance for our certifications:

- ISO Certification – Machine Shop and Foundry

- ASME BPVC Section III, Part 1, NCA-3800

- ASME NQA-1

- 10CFR50, Appendix B

- MIL – I – 45208

- MIL – Q – 9858

- NORSOK M-650

To assure our compliance our system includes:

- Quality Policy Manual

- Quality Management Procedures (QMPs)

- Work Instructions (WIPs)

- Safety Management Procedures (SMPs)

- Provider Handbook

Special Processes Employed

Stainless Foundry & Engineering perform NDE, welding and heat treatment internally or outsourced to qualified & approved sources.

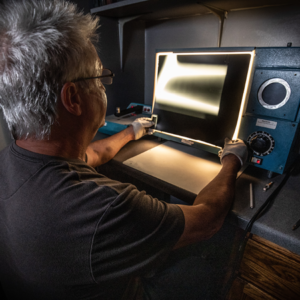

NDE – (liquid penetrant, magnetic particle, radiography (X-Ray, visual, ultrasonic) Certified to the requirements of ASNT SCT-TC-1A and MIL-STD-410 by Stainless Foundry & Engineering and its approved providers.

WELDING – Welders certified to the guidelines of ASTM A488, ASME BPVC Section IX, MIL-STD-248 & S9074-AQ-GIB-010-248“. They are also qualified welding procedure specifications to European requirements EN ISO 15614-1.

HEAT TREATMENT – Performed internally and outsourced to numerous different industry standards both in-house and at approved providers.

Traceability and VERIFICATIONS

Each lot of material is traceable through the heat number (and serialization as required). There is a computerized floor system that personnel clock on and off jobs for electronic sign off for traceability. Which also provides operator instructions and pictorials for use during the operation.

Travelers follow shop orders through the foundry and machine shop when special instructions are necessitated by the customer or to ensure internal controls.

Chemical analysis, mechanical testing as well as metallurgical evaluations including metallographic analysis capabilities exist in-house

Final inspection is performed to the requirements of ANSI-Z1.4, MIL-STD105E or MSS SP-55

We conduct dimensional inspection of the patterns, dies and castings employing CMM layout.

Certifications are completed on Level 1 (nuclear or governmental), 2, 2E and 3 (commercial) criticality levels.

Continuous Quality Improvement

The basic building blocks of quality – flow diagrams, PFMEAs, control plans, measurement analysis, and layered audits are performed providing a firm foundation

The use of Lean & Six Sigma practices assist in continuous improvement

Our pledge is to provide our customers with quality casting to exceed your needs

With our value statements of: Respect, honesty, teamwork, accountability, responsiveness and work-life balance

Stainless Foundry & Engineering, Inc. is committed to on-time delivery of products and services that conform to our customers’ requirements at a competitive price with minimum lead times. This commitment is fulfilled through the use of preventive action programs and a dedication to the philosophy of “Do it right the first time.”