Your Career Starts Here

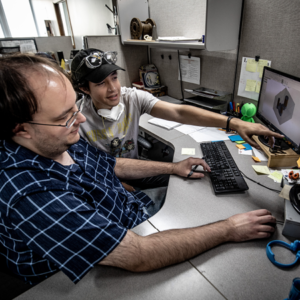

Stainless Foundry & Engineering, Inc. manufactures a complete line of quality sand and investment castings providing innovative solutions to the specialized casting needs for a variety of customers. Looking for a fulfilling foundry or engineering career? We offer a competitive salary, and a comprehensive benefit package. Check out which positions are open below.

Due to continued growth, Stainless Foundry & Engineering, Inc. continually searches for key people to join our high performance manufacturing team.

From time to time, we have openings in Engineering, Quality, Maintenance, and Machining.

Stainless Foundry & Engineering, Inc. offers a wide variety of benefits including:

- Medical Insurance

- Dental

- Vision

- Matching 401k Plan

- PTO after 90 Days!!!!

- 11 Paid Holidays

- FREE Life Insurance

- Short-term Disability

- Flexible Spending Accounts

To apply for a position fill out the Employment form to the right or print the employment application and mail to:

Stainless Foundry & Engineering, Inc.

5110 N 35th Street, Milwaukee, WI 53209

ATTN: Human Resources