Solidification and Solid Modeling

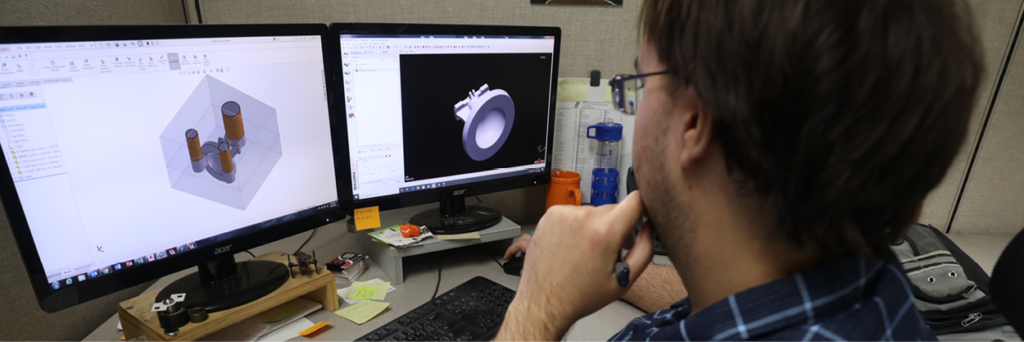

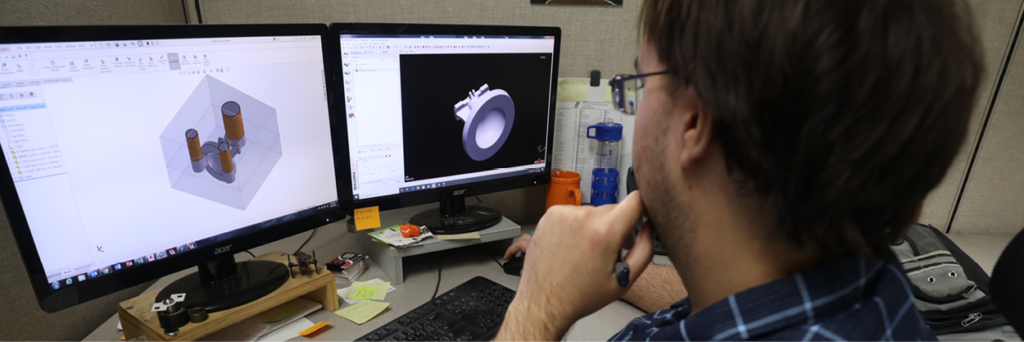

Stainless Foundry and Engineering team of Foundry Engineers utilizes SOLIDWORKS solid modeling software as well as MAGMASOFT solidification.

The duty of our engineering department is to provide a custom design that will function properly and save our customers time and money. We use SOLIDWORKS to create gating and rigging solutions to provide high quality casings. The powerful use of SOLIDWORKS software allows us to increase productivity and leverage 3D solid modeling to better assist our customer in quickly deploying their innovative product.

We utilize SOLIDWORKS for our solid modeling and encourage you to send in your models to see what we can do for you. For solid model files we request SOLIDWORKS files, Step files (.stp) or Parasolid files (.x_t)

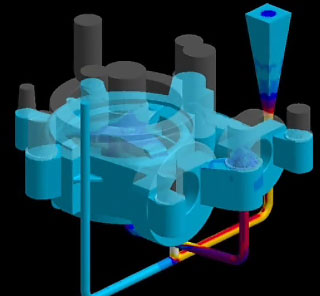

To improve our first time yield and to make quality / manufacturing improvements, we utilize MAGMASOFT solidification to predict casting soundness. After gating and rigging the castings we use MAGMASOFT solidification software to analyze the gating and rigging solution to ensure that we engineer a high quality casting solution on the first run and every time we produce your casting.

Investing in technology is why we succeed. Using autonomous engineering allows for quick decision making, clear communication and a more systematic understanding between us and our customers. The use of MAGMASOFT gives all of our customer’s a higher quality of metal casting, a clear vision of the process and conditions all the while reducing cost of production for all casting materials.

If quality is your issue it might be the uncertainty in your current engineering process. Let us be your foundry of the future – today.