Foundry Metallurgical Testing

Since our founding, we have continually pursued superior foundry metallurgical expertise. Over the years, we have amassed considerable experience and data – resources that are available to you. You can call on us for help with Alloy selection. The Metallurgical Department at Stainless Foundry includes a staff of full-time degreed metallurgists responsible for the foundry metallurgical testing. They are available for discussing properties, selection, application, and specification of Alloys. They can tailor Alloys to your specific application when a standard grade is inadequate and provide failure analysis services. Support is provided by Metallurgical and Laboratory Technicians, and a full complement of laboratory equipment.

On site chemical analysis equipment includes optical emission spectrometers, a carbon/sulfur analyzer, and a nitrogen/oxygen analyzer. These instruments permit close control of the metal composition at all phases of the process and provide final heat analyses for test reports.

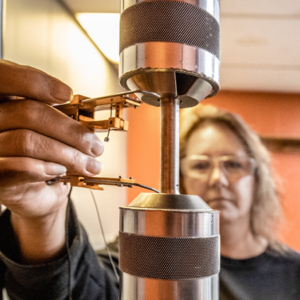

The Metallurgical Testing Laboratory includes lathes for machining test bars, a 60,000 lb capacity tensile testing machine, and Brinell, Rockwell, and Rockwell superficial hardness testing machines.

The Metallographic Laboratory has all the equipment and supplies needed for cutting, grinding, polishing, and etching samples for metallographic examination. The metallograph allows visual examination at magnifications to 2000 X and photography to 1500 X. A closed-circuit TV system allows group observation and discussion of the microstructure of the samples.

All these capabilities are supplemented as needed by outside, independent laboratories.

Please see the Contacts page to contact our “metal chefs” with your foundry metallurgy questions. Metallurgical expertise is our strength. Alloy modification, process changes to meet special needs, and improved production techniques are major thrusts.