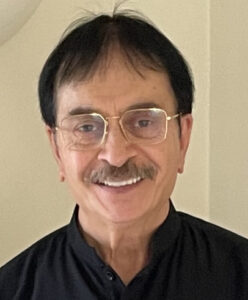

Foundry Expert Vijay Talwar Joins Stainless Foundry & Engineering as Director of Metallurgy & Process Engineering

Process engineer will leverage 40+ years of expertise to optimize foundry methods

Stainless Foundry & Engineering (SF&E) is pleased to announce the addition of Vijay Talwar as Director of Metallurgy & Process Engineering. Talwar brings with him over 40 years of foundry experience with significant knowledge in process engineering, metallurgy, alloy development, and the markets SF&E does business in. In this new role, Talwar will work closely with SF&E quality, operations, and engineering teams to support continuous improvement to foundry processes to help reduce scrap and optimize output for SF&E customers.

Stainless Foundry & Engineering (SF&E) is pleased to announce the addition of Vijay Talwar as Director of Metallurgy & Process Engineering. Talwar brings with him over 40 years of foundry experience with significant knowledge in process engineering, metallurgy, alloy development, and the markets SF&E does business in. In this new role, Talwar will work closely with SF&E quality, operations, and engineering teams to support continuous improvement to foundry processes to help reduce scrap and optimize output for SF&E customers.

SF&E has spent the last four years prioritizing continuous improvement efforts around the foundry to advance quality and overall performance for customers. Progress has involved new equipment purchases, production process changes, separating commercial work from high specification work, introducing (and bringing back) new alloys, as well as new partnerships with vetted third parties to supplement capacity. SF&E’s investment in its people, such as Talwar, progresses the foundry’s technical capabilities.

“We have been fortunate to work with Vijay for the past several months through a consultation relationship to further improve our processes here at the foundry,” shares Jim Stachowiak, President and CEO of Stainless Foundry & Engineering. “Vijay has an impressive portfolio of experience and proficiency in the key industries and core parts we excel in as a foundry, as well as extensive knowledge in metal mixes and melts. Having him join the team is a huge advantage for SF&E and our customers.”

Talwar’s process engineering and foundry background spans across industries such as food and beverage, defense, and oil. Talwar is Six Sigma Black Belt certified, as well as versed in a wide array of alloys. Some of those alloys are stainless steel, non-galling alloys, copper-base alloys, carbon, and low alloy steels; corrosion and heat resistant alloys as well as high alloys like invar, Inconel, IN-100, aluminum alloys, cast iron, and ductile iron. He holds a bachelor’s degree in Metallurgical Engineering from Punjab Engineering College, Chandigarh, India.

About Stainless Foundry & Engineering

Stainless Foundry & Engineering is a manufacturing industry leader in sand & investment castings offering heat treatment, non-destructive testing, and rough or finish machining. Pouring over 250 alloys, we primarily work for top sectors in the military, food and dairy, petrochemical, nuclear, power generation, oil & gas, and various pump and valve avenues. With annual shipments north of 4 million pounds of castings produced in weights ranging from grams to 7,000 pounds, SF&E has the technical competence and manufacturing expertise to satisfy the requirements of highly complex casting projects.

To work with Vijay on an upcoming project, please email sales@stainlessfoundry.com, call 414.535.6089, or request a quote.