The casting for a large, closed impeller manufactured by Stainless Foundry & Engineering (SF&E) has a final ship weight of 2,500 pounds. It is a nuclear service part that was produced at a high specification. In order to leave the foundry, the impeller must pass some critical acceptance criteria.

First, the impeller has to meet the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code (B&PVC) Section III, Division I, Subsection NB for Class 1 construction. The material is ASTM A487, grade CA6NM, Class A. This is a fine-grained martensitic stainless steel alloy, which is magnetic in nature.

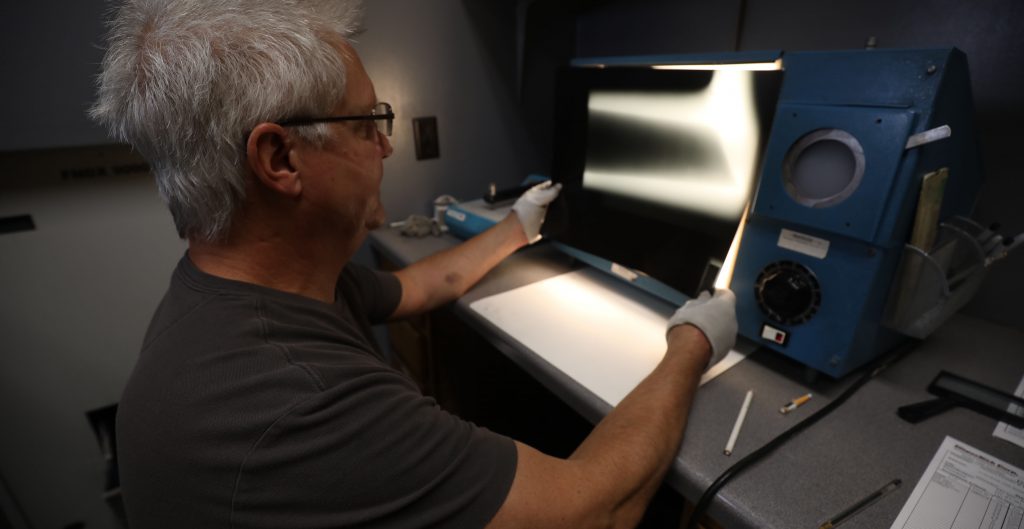

The only way SF&E and its customer can be certain the closed impeller passes the customer’s purchasing requirements is to run a series of non-destructive tests (NDTs). This means the quality must be confirmed without causing destruction or damage to the part.

NDT is primarily used to evaluate and safeguard the integrity of castings. Many different techniques can be administered, from using a method as basic as visual testing to a method as complicated as ultrasonic testing – all escalate the level of precision.

The requirements placed on castings at the design phase of a project specify the method and acceptance criteria of the casting. In the case of the closed impeller casting, the customer required testing and certification for 100% Radiographic Testing (RT), Magnetic Test (MT), Visual Testing (VT), or visual inspection.

The technicians that perform the NDT in the foundry industry are specially trained personnel. Formal training along with on-the–job history or experience is vital to success.