“When I was young, my father told me something I will never forget. He employed 100 people at Stainless Foundry at the time, and said to me, ‘We don’t have 100 people working with us, we have 100 families who depend on Stainless Foundry for their livelihood.’ It meant so much to him,” said John McBroom Jr., former CEO of Stainless Foundry & Engineering and son of John McBroom Sr., who co-founded Stainless Foundry in 1946. “How you treat people, how you grow a business, what you do to survive – my father’s values were so important to me, and I am proud to say we kept that. You have to be able to look yourself in the mirror.”

Stainless Foundry Celebrates 75 Years of High Quality and Dependable Service

The foundry industry has gone through a lot of changes since 1946, and even since the 1960s when McBroom joined the ranks doing maintenance work as a teenager.

“From the 1960s compared to today, probably 80 percent of foundries in the U.S. have closed,” McBroom said. “Foundry work is labor-intensive, which is one of the primary reasons businesses moved offshore. To survive, you have to change, and that is one thing we were able to do.”

Stainless Foundry & Engineering has new ownership since McBroom retired, but the commitment to continuous improvement in the best interest of customers and employees is the same. It’s also what makes SF&E unique in the industry.

“We understand our customers are competing in a market that is driven by lead time, availability, quality, and price. At the same time, employees are competing in a market that is driven by skill and experience. SF&E believes the two go hand in hand,” said Jim Stachowiak, President and CEO of SF&E.

A Legacy of Customer Service

SF&E started out as a sand foundry that focused on closed impellers for pumps and parts that were intricate and difficult to cast. Service offerings and expertise expanded as SF&E received feedback from customers on their needs. It’s why in 1953, SF&E purchased a Illium Corporation, acquiring a series of patents to special corrosion-resistant alloys. And in 1968, SF&E added investment casting to help meet industry demand for precision parts. It’s also how SF&E developed strong technical, engineering, and manufacturing departments that work with more than 250 alloys and this year, poured parts weighing up to 7,000 pounds, all while providing dependable service.

But one conversation McBroom had with a customer in Minneapolis decades ago set SF&E on a different course that other foundries would not catch up to quickly, if ever.

“The customer wanted more communication and customer service from us. He said there were times he would call to ask a question and would never get a response,” McBroom said. “We took that feedback seriously and started a foundry-wide campaign that involved all employees, but especially the ones dealing directly with clients, to make sure they understood the importance of getting back to a customer – even if it was just to say you are still working on an answer. I think this was instrumental in helping us survive because it was a major change in how a foundry dealt with people.”

This had a positive snowball effect that continues today. An emphasis on customer communication led to a review of process and efficiency. McBroom’s management team identified that sand casting production would be more efficient if it were poured, cutoff and basketed in one area of the foundry, then welders would grind and markup imperfections before welding. This improvement cut down on the distance a part traveled around the foundry by 80-90%. This unlocked the ability to significantly reduce lead times.

“Where others in the industry were complaining about customers demanding shorter lead times, we were gaining new business and setting ourselves apart,” McBroom said. “We had happy customers who, because of our lead times, were able to make efficiency gains themselves, for instance, by reducing their parts inventory.”

Under Stachowiak’s leadership, SF&E is currently undergoing a multi-year, multi-phased Throughput Improvement Project that involves capital investment in employee training and certification, additional equipment, and updated floor plans to ensure parts can be produced and ready to ship within 4 weeks.

The Throughput Improvement Project will allow SF&E to double its foundry capacity for blasting and cleaning room operations, make room to concentrate on high specification work, and bring more specialties in-house.

“Lead times are important because our customers need to forecast their own inventory, production, and delivery needs around them. A drastically reduced lead time could be critical; manufacturers can eliminate inventory guess work, react more quickly to customer demand, get to market faster, and, ultimately, increase the profitability of their products,” Stachowiak said. “It also provides our employees a career development path that expands their skill level and provides increased responsibility.”

A Reputation for Employee Retention

Employees are key to this story. They share a commitment to doing good work that serves the customer’s best interest. It was because of this employee commitment that SF&E has been able to analyze, plan, and implement the changes that made it successful today.

The McBrooms aren’t the only family legacy that was formed at Stainless. Scott Schwulst, SF&E Maintenance Director has worked for SF&E for 40 years and is a third-generation employee, following in the footsteps of his two grandfathers, two uncles, and his father. Scott’s family and their passion for metal work, their fulfillment in working for the company, as well as his personal experience learning about metallurgy through a high school program, influenced his decision to work in the foundry from a young age. To Scott, SF&E is an extension of his family. Scott has worn many hats and served in a variety of roles such as Lead Welder, Director of Machine Shop, and Quality Director, to name a few.

“SF&E is proud of its tenured employees who have dedicated their careers to SF&E and hopes to continue that tradition with newer members of our team,” Stachowiak said.

David Jackson, Core/Mold Maker, started in 1974 and comes to work every day because of the atmosphere and workmanship. “It makes me feel good that I put out a product that looks good. Customers have written letters thanking us, the McBrooms and now new management will compliment us on our work… It makes you feel good to get up in the morning,” Jackson said.

Donna Kittler has worked for SF&E for 29 years. She started out in the wax room and has worked her way up to her favorite job to date, Wax Assembly Lead. “I love seeing all the new jobs coming in and I am the first one who gets to assemble them. Stainless is a good company to work for,” Kittler said.

Aaron Knapp is the CFO and Vice President of Finance for SF&E. In his four-plus years with the company, he has witnessed how all employees benefit from the opportunity to work in different functions and aspects of the business. “From the manufacturing standpoint, there are many opportunities to grow and earn new certifications. You can tell by the fact that the average tenure of manufacturing employees at SF&E is significant. On the professional side, Stainless offers a great learning ground and the opportunity to take on more responsibility earlier in a person’s career,” Knapp said.

Taylor Siech has been with SF&E over four years as well. She currently serves as the Production Control Scheduler but started at reception, moved into customer service, and continued to grow and take on more responsibility until she landed in her current role. Taylor is inspired by the passion at SF&E. “You look at people who have worked here for 30 years, 45 years, and they are still so passionate when they come to work. They love what they do. They love the hard work, grit, and elbow grease, but we also have fun. Stainless to me is about quality, passion, responsibility, safety, a good work environment, and good products. I have learned so much about the foundry industry from when I started, and I just want to continue to grow,” Siech said.

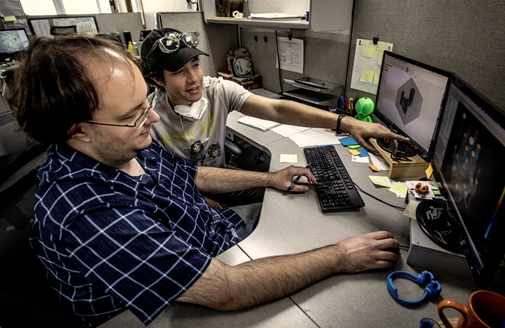

Anthony Geiger has served as an Investment Foundry Engineer at SF&E for 3.5 years. “I am mostly proud of all the military work we do. It is important to me to be doing something that makes a difference. I also enjoy working alongside people who have worked here for so long. They have become mentors and good friends. It is a family-oriented style of workplace.”

Scott McCallister, QA Dimensional Engineer, has been with the company for 14 months. “We take a lot of pride in what we do. I like that we have quite a few technical people at Stainless. We provide help and support to each other. We benefit from multiple perspectives and instead of looking up everything on your own, you have people you can rely on,” McCallister said.

Justin Chamberlin started at SF&E in 2020 as Technical Director. He joined the foundry because of its reputation for innovation. “I chose this job because it is technically rewarding. I like to be able to come into work and problem solve until we figure things out. There are technical challenges aplenty here – from all the different alloys we make, to all the different parts and shapes and processes we use, it is very rewarding,” Chamberlin said.

So, what is the secret to another 75 years of success?

“We bring a lot of knowledge to the table and there are very few challenges we are not willing to take on,” Chamberlin said. “We will experiment, try something new, and our 75 years of experience in making just about everything puts us in a good position for the future.”

If you are interested in learning more about our history, or are ready to give us our next challenge, contact us today at sales@stainlessfoundry.com. If you’d like to join the 75-year celebration, comment, like and share our LinkedIn and Facebook posts that feature employees, parts, and blasts from the past.