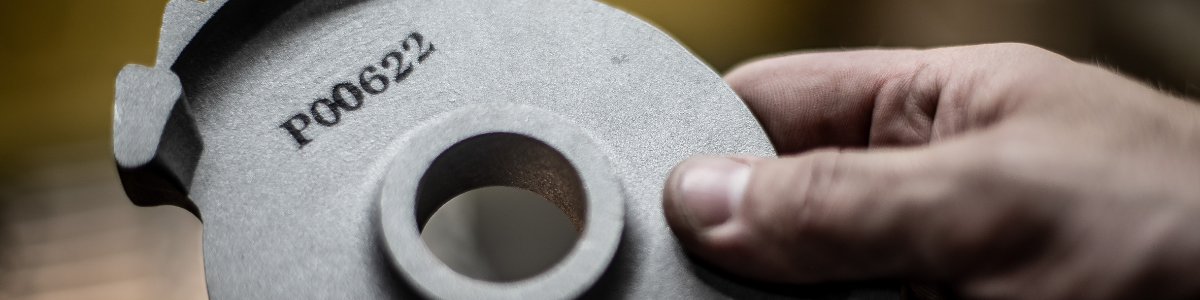

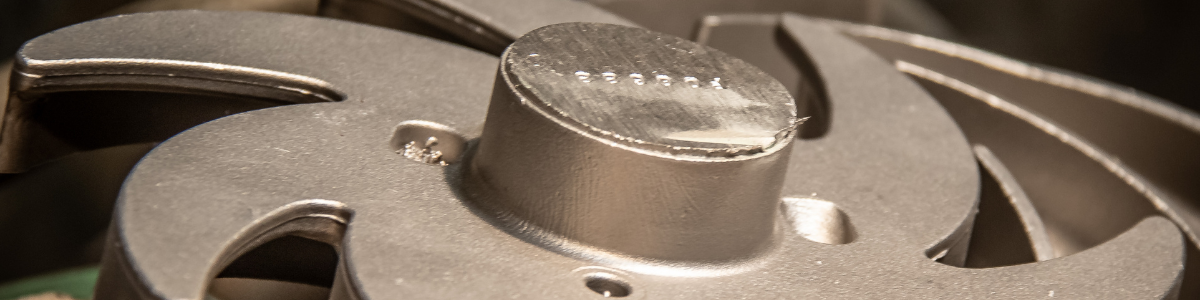

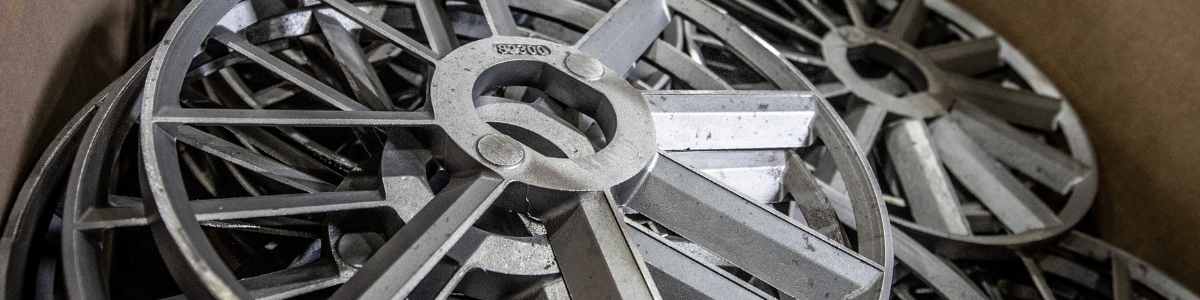

Stainless Foundry & Engineering is a One Stop Shop. We offer two foundries in one, a sand casting division and investment casting division, together with Machine Shop services. As your single source for dual casting processes, there’s no need to work with two foundries for the different types of casting and we can also recommend which might best fit your requirements. Our sand casting capacity ranges from 50 lbs. to 7,000+ lbs. furnace capacity, while our investment castings range from less than 1 lb. to 350 lbs.

Over 250 alloys are poured at SF&E, with groups including: Stainless Steel, Hardenable & Non-Hardenable, Heat-Resistant Stainless, Nickel Alloys, Cobalt Alloys, Carbon & Low-Alloy Steels, Cast Irons, Tool Steels and Specialty Alloys.

Our Machine Shop services include specialized turning and milling machining services. Our machining capabilities range from ounces to 600 lbs and enable us to manufacture parts with intricate geometry and detail while maintaining high precision and accuracy.

Industries we serve

Our Brand New Tools To Make Your Job Easier

We are proud of our current certifications/qualifications

Stainless Foundry & Engineering was the first US foundry certified to the Pressure Equipment Directive 97/23/EC when it became available in the US. We now hold the largest scope of materials approval to the current Pressure Equipment Directive 2014/68/EU, including:

- 2014/68/EU

- ISO 9001:2015

- NIAC (Nuclear Industry Assessment Corporation)

We can meet the following requirements:

- ASME NQA-1: 2015, ASME BPVC, Section III, Part 1, NCA-3800/NCA 42100

- 10CFR Part 50 Appendix B

- NORSOK M-650 • OPSEC