Can Castings be Welded?

The world of fusion welding has effected many industries and fabrication opportunities worldwide. Countless industrial items are assembled using a vast number of different welding techniques governed by numerous rules, codes and norms. Casting upgrade welding is a very specialised series of operations. The casting process offers a unique opportunity as the casting is an economic preform. Weld upgrade is inherent to the process. This article investigates the processing sequences required to perform welding on cast stainless steels and other alloys.

The inconvenient truth – welding of castings

We need to ask ourselves, why a casting? A casting is many things to many people. Firstly, a casting is an economic preform. By this, I mean

that it is a shape made in sand or an investment mould. Many shapes are only possible to make with this process. Take a complex pump casing with many passages and blind holes as well as a thin cut water feature; these features cannot be made economically as a forging or from a wrought block of steel. A casting is superior due to its equiaxed grain structure and is much more corrosion resistant than a wrought material of a similar shape.

An important benefit of a cast product is that it is weldable, as compared to other manufacturing techniques. A disadvantage is that the casting may not have the same strength or wear resistance as a forging or other form. As long as the design is correct for the application, a sound casting can be beneficial as an economic preform (saving you the time and cost of machining from a larger shape as well as expensive tool costs). Weld upgrading is part of the process of producing a casting of high integrity as well as commercial items.

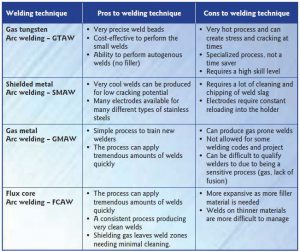

Common welding techniques are used in a foundry to weld casting defects such as sand inclusions, shrinkage porosity or other foundry defects. Welding processes such as shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW) and flux-cored arc welding (FCAW) are a few of the common techniques used (Table 1).

Welding codes

Welding is permitted and endorsed by practically all materials codes. All American material codes such as ASTM A351, A487 and A995, to reference a few, allow minor and major welding of castings. European material codes such as EN10213 have welding allowances for repair or upgrade activities. Welding being an engineering centric process requires controlled oversight concerning repair or upgrade on castings through technical codes and specifications.

There are essential, supplementary essential and non-essential variables referenced in the American Society of Mechanical Engineers (ASME) codes. The American Society of Materials Testing (ASTM) also has welding conditions that need to be complied with. European welding codes carry requirements for tensile strength and weldability tests such as weld bends. Many of these tests are common to both American and European specification agencies. Together these create verifications and compliances to ensure safety, metallurgical integrity and a standardised process.

Personnel qualifications for welders and welding operators are tightly woven into the codes and norms that regulate good welding practice and technique.

In many instances, welders must undergo performance tests before they are allowed to perform welding and casting repair to establish confidence in their performance. Radiography, visual inspection and/or weldability tend to be the standard tests that are performed for all welding codes.

Tools and methods for weld repair

After a casting has been inspected and defective areas have been marked, these locations need to be excavated. To perform a proper weld the weld area needs to be cut or ground down to sound metal. Figure 2 shows some of the tools used to perform this cleaning and weld excavation preparation. One of the most useful tools to excavate with is a heliarc torch. The area of interest can be swiped free of defects, burrowing down until clean metal has been obtained. Another technique employed is an abrasive wheel which grinds the pocket clean. Additional tools which can be useful include carbide burrs and abrasive stones. All of these will polish an excavation and prepare it for welding.

To continue reading click the links below or download here.

If you’d like to speak to someone at Stainless Foundry and Engineering about your next project, contact us today by clicking here.