A centrifugal pump moves liquids including water, beverages, chemicals, oil, and gasoline through a pipe at high flow rates. An engine or motor activates an impeller within the pump, which uses centrifugal force to pull fluids through a volute, and then pushes liquid out through acceleration. Centrifugal pumps come in all sizes and are relied upon by many manufacturing, industrial, and agricultural industries.

More than 75 years ago, Stainless Foundry & Engineering (SF&E) was established with a focus on closed impellers for pumps and other parts that were difficult to cast. Over the years, SF&E has developed leading technical, engineering, and manufacturing departments that work with more than 250 ferrous and non-ferrous alloys to pour parts up to 7,000 pounds. Even as we have expanded our service offerings and broadened our expertise over the years, pump parts continue to be one of our strengths.

In the following, we break down the anatomy of a centrifugal pump – from the precision of the parts to the significance of the alloys.

Parts of a Centrifugal Pump

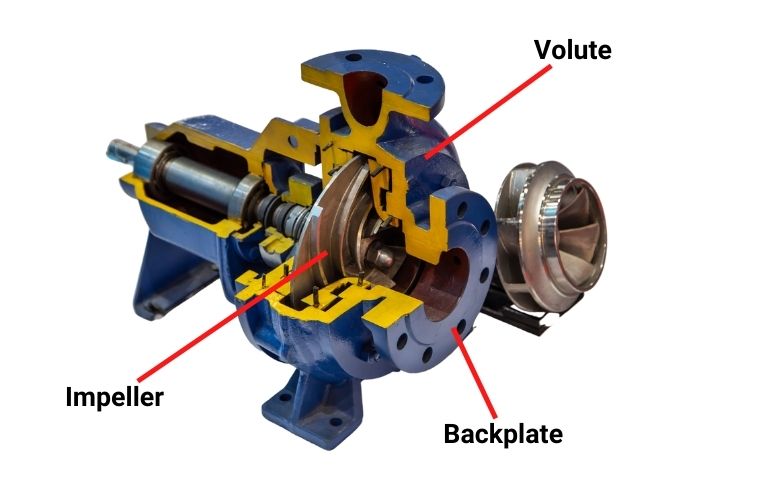

A centrifugal pump has five main parts: the casing – called a volute; the impeller – which is used to move the liquid; the backplate that acts as a seal for the impeller; bearings; and the shaft that connects the impeller to an engine or motor. Below is an image of a sectioned centrifugal pump with all parts in place and in view.

A pump’s volute or casing is made up of one or two castings: a single piece or one split into upper and lower casings. The volute is the pressure or non-pressure retaining housing of the impeller and pump drive system. It can be vertical or horizontal, depending on the pump shaft, element bearings, and impeller.

The impeller is the working part of the pump that is designed and produced to move liquid. It can be used to move water, slurry, food, dairy, or highly corrosive materials. There are three styles of centrifugal pump impellers: open, semi-open, and closed.

The backplate covers the impeller inside the volute or casing. It is the sealing element of the pump casing and holds the internal components of the pump in place. The main intention of the backplate is to use a casing that does not have a suction funnel built internally.

SF&E produces volutes, impellers, and backplate parts of a centrifugal pump – including all three styles of impellers. We also produce multi-stage centrifugal pump casing castings, which house multiple impellers that connect a series of liquid chambers.

Multistage Centrifugal Pump with Multiple Impellers

SF&E is a prominent supplier to OEMs serving the chemical, petrochemical, nuclear, pulp and paper, pharmaceutical, food and dairy, metering, and military markets with corrosion-resistant, high heat, and wear resistant steel, stainless steel and high alloy parts.

The structure and the alloy chosen for each centrifugal pump are key elements to consider depending on the type of application.

Alloy Selection

Over 250 alloys are poured at SF&E, with groups including: stainless steel, hardenable and non-hardenable, heat-resistant stainless, nickel alloys, cobalt alloys, copper base alloys, carbon and low-alloy steels, cast irons, tool steels and specialty alloys. Alloys used for centrifugal pumps depend on the material the pumps will need to move and the environment they will be placed in.

Stainless Steel – SF&E produced the core parts of a 12-stage pump, including the split upper casing, lower casing, and impellers. Below is a photo of the casing. The parts were cast in martensitic stainless steel, which provides mechanical strength and superior corrosion resistance to endure the conditions of a nuclear environment.

High Chrome White Iron – High chrome white iron grades are commonly used in pump parts for the mining, agricultural, and paper industries with applications that work with slurry and cement. Parts poured with ASTM A532 Class III Type A contain 25% chrome white iron, are corrosion resistant and wear-resistant due to their high hardness, specific chemistry, and heat treatment.