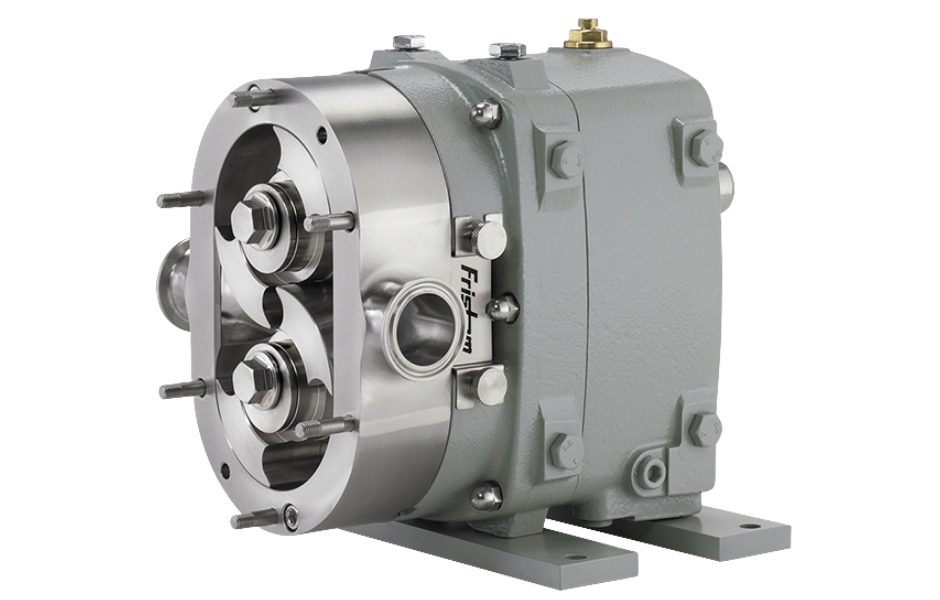

When you walk through a grocery store, anything that is contained in a bottle, can, or tube most likely utilized a pump in the production process. From the milk processor removing milk from a tanker truck to the toothpaste manufacturer filling tubes, pumps make it all possible. Fristam Pumps is the leading manufacturer of high quality, sanitary stainless steel pumps, blenders, and mixers in the food, beverage, and pharmaceutical industries. Their pumps are designed, manufactured, assembled, and tested in Middleton, Wisconsin.

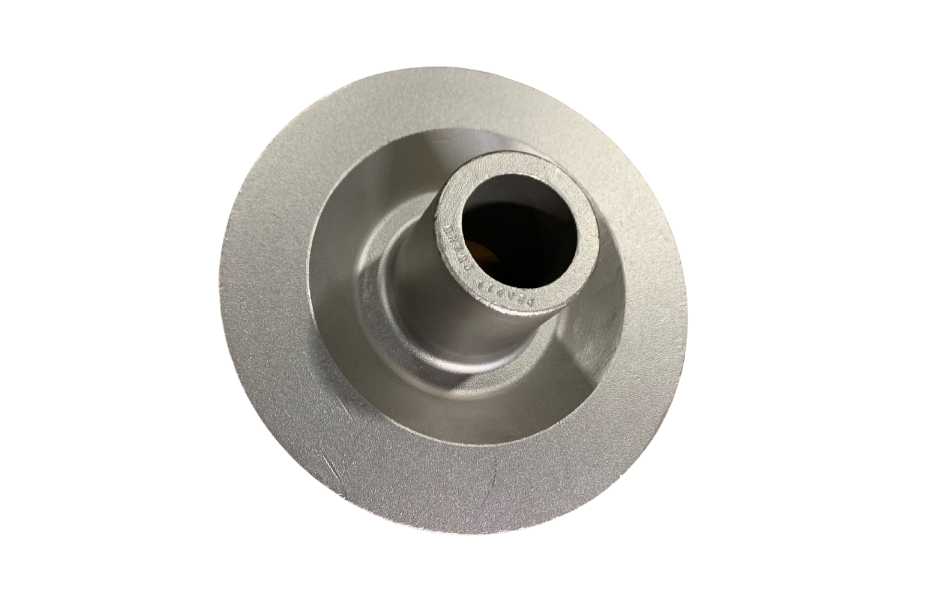

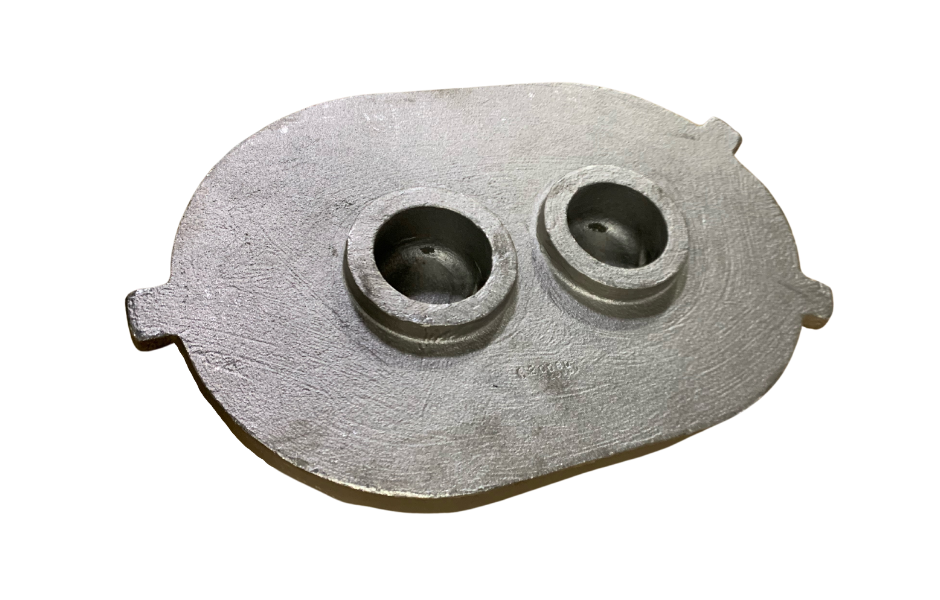

Fristam enlisted Stainless Foundry & Engineering (SF&E) more than 20 years ago to produce sand and investment castings for their proprietary pump parts, which come with critical requirements. Some of the requirements are related to specialized alloys – different variations of 316L stainless – and some to a high-level interior finish. The requirements are in place to ensure long-lasting quality and avoid the potential for bacteria accumulation.

“When it comes to performance and efficiencies of moving material, we offer a very high end, precise pump that is cleanable, durable, and serviceable,” said Gary Ehnert, Materials Manager for Fristam Pumps. “We cannot put ourselves in a situation where we have to question the integrity of the casting and the metal that was used to produce that casting as we are building a pump.”