High Spec Castings – What You Need to Know about Testing

Submarines dive, ships sail, petrochemical facilities operate leak-free, and fighter jets soar. These applications, along with many others, depend on reliable, high-quality castings produced to withstand demanding conditions.

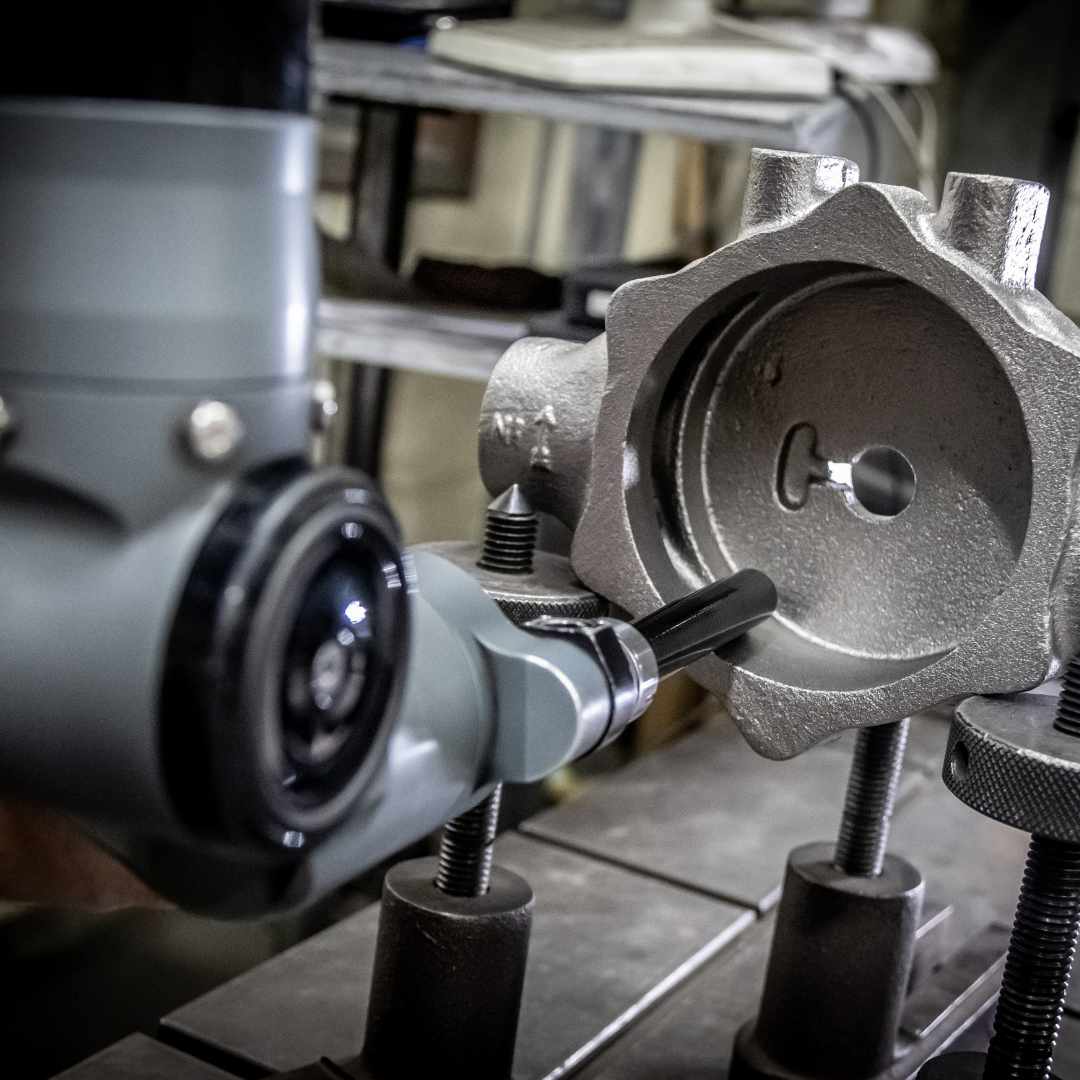

Stainless Foundry & Engineering (SF&E) casts parts that require a high level of specification in the nuclear, petrochemical, power generation, military, and defense industries, among others. Thorough testing is imperative to ensure these critical castings not only meet customer and industry standards, but they have the structural integrity to perform throughout their expected service life.

Dedicated metallurgists, process engineers, foundry engineers, and quality assurance personnel at SF&E execute highly specialized processes to produce a casting, evaluate its quality in a non-destructive manner, and then safeguard that it will meet all acceptance criteria.

We’ve been able to do this successfully because of a series of procedures we have put in place throughout all aspects of production. It all starts with clear communication.

Laying the Groundwork

Before any project begins, SF&E conducts a multiple level review of the contract (purchase order) to ensure our routings are built to be within compliance. The casting may require any or all of the following requirements, which SF&E has demonstrated to excel at for decades:

- Various non-destructive testing (NDT) methods,

- Government obligations such as a site witness,

- Customer purchase-order specific mandates such as pressure testing or third-party chemical analysis,

- Dimensional testing,

- Metallurgical tests such as micro evaluation or even corrosion testing.

Our customers provide the technical specification requirements on mechanical properties, cast hardness, and other factors. And when necessary, there will be compliance with EN/ISO pressure equipment regulations. The final plan is developed based on manufacturing methods that have been proven over the 75+ years SF&E has been pouring castings. Once all the required inspection and testing operations are reviewed, non-destructive examination (NDE) technicians – including level II and level III professionals – must submit their technical procedures and time personnel records to agencies for approval.

Ins

Inspection and Testing

NDE/NDT is necessary to determine if the cast part conforms to the purchase order

Other testing techniques include: requirements. Given the various demands on high-specification castings, these parts require qualification both on the surface and volumetrically. Considering the range of needs these castings must handle, SF&E offers a variety of NDE/NDT testing methods, including MSS SP-55 and ASTM A802 visual inspection specifications, however we know that most high specification castings come with their own requirements. Radiography, magnetic particle, liquid penetrant, and ultrasonic testing provide additional assurances that the parts meet the acceptance criteria that was specified from the beginning.

- Dimensional Testing – Physical measurement to verify compliance with customer drawings using electronic devices including coordinate measuring machines (CMMs), dimensional scanners, and other electronic hand tools that download measured readings. Reports pertaining to final dimensions are necessary for an order to be considered completed.

- Positive Material Identification (PMI) – A hand-held unit analyzing chemical structure to confirm that the material in the casting conforms to the certified chemistry in the specification. Many industries including oil and gas and power generation require their products to be verified on a pallet prior to shipment.

- Optical Emission Spectrometry (OES) – A highly rapid and very accurate means of confirming the chemical composition of a metallic sample. SF&E pours more than 250 alloys. In addition to meeting customer specifications for alloys, Ni, Cr, Cu, Mo, and Si are residual elements that can be of concern in certain steel grades because they control weldability, grain refinement, microstructure, and responsiveness to heat treating.

- Tensile Testing – An application of pulling force on a test material in two opposite directions to determine how strong a material is and how much deformation it can withstand. Tensile testing is generally performed on an electromechanical or universal testing machine.

- Hardness Testing – A way to measure the surface quality of a cast material. It can be an indicator of material performance based on its intended application. SF&E follows ASTM guidelines on hardness testing to ensure repeatability and accuracy are maintained through an industry standard.

- Corrosion Testing – An important metric when certifying certain high specification cast alloys, widely used in the oil and gas and nuclear industries where there are high vulnerabilities for pressure leaks.

Once a part has been inspected and tested, the reports from those tests, as well as the original specifications, need to be submitted with a great level of precision and attention to detail. The contract review, inspection, and material testing of the casting are all crucial to ensure that all identifying criteria are met during production.

Covering All the Bases

Covering All the Bases

Our entire team at SF&E knows that when it comes to producing high specification castings there are various regulations and customer specific requests that must be followed. This requires the foundry to verify that the steps and operations for testing are correct and processed by properly qualified technicians and certification personnel so that they produce to the highest quality and standards.

If you would like to know how SF&E would handle qualification testing and inspection of your high spec product, contact us today at sales@stainlessfoundry.com.