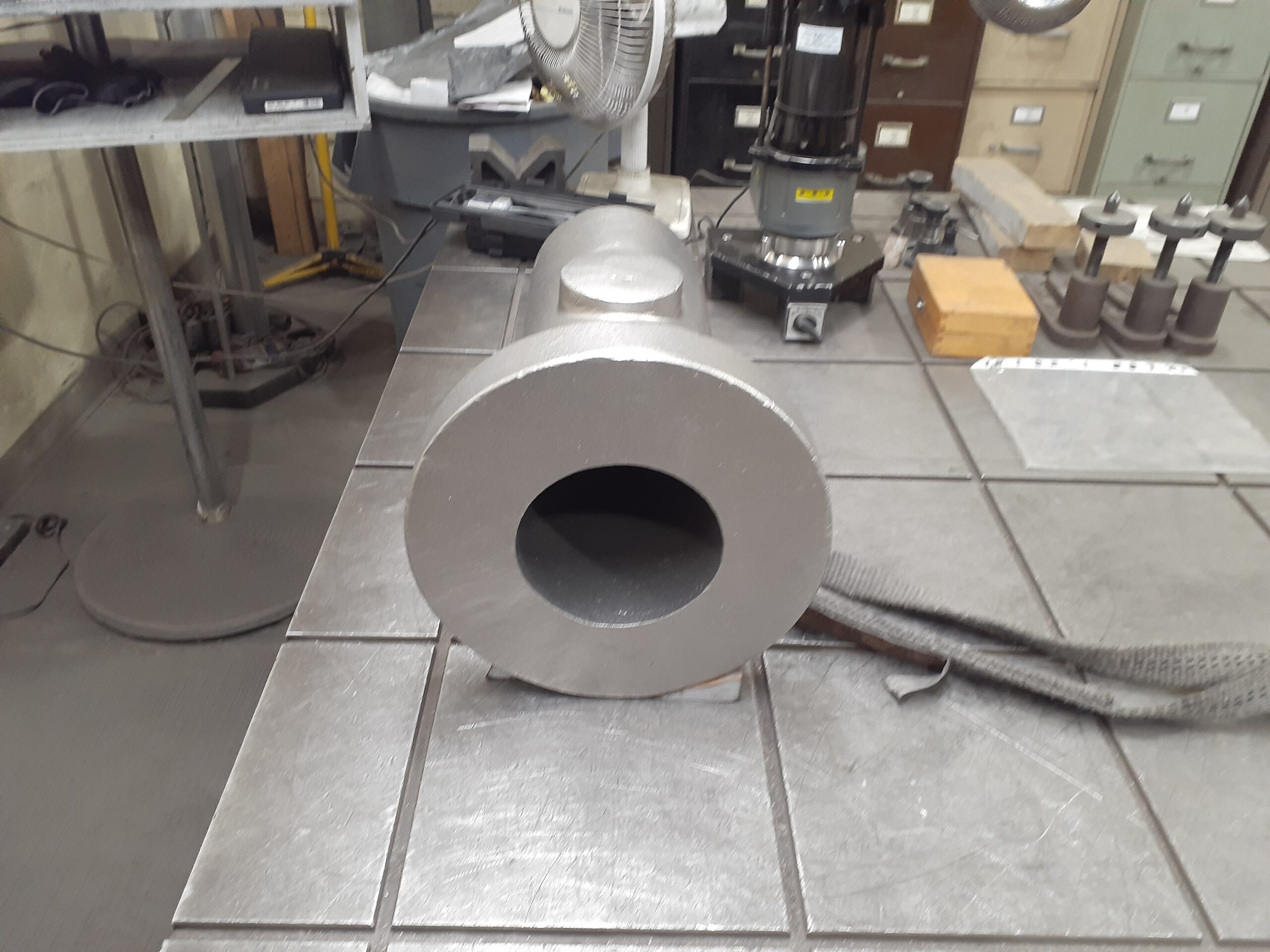

Production can only be as smooth as a facility’s material flow. For Hydro-Thermal, the global leader in the development and manufacturing of Hydroheaters, production cannot be interrupted. When working with suppliers, product quality and delivery time are paramount – especially when it comes to one critical part. The diffuser controls how steam is injected into fluid in a Hydroheater. Hydro-Thermal has relied on foundries to produce the diffuser in 2-part castings, which are then machined, welded, and machined again by Hydro-Thermal to create one final piece.

“How we design the diffuser is important. The pattern and location of the holes on the diffuser ensure that our customers achieve efficient heat transfer for their specific application. The part design is critical to making that process happen continuously,” said Derek Rowland, Director of Operations for Hydro-Thermal.

Before partnering with Stainless Foundry & Engineering, Hydro-Thermal worked with a foundry that had difficulty living up to their expectations. Delivery times were promised and missed. Porosity in the castings was a constant struggle. Rowland had worked with SF&E before, so reached out to see what we could do to help.

SF&E foundry engineering considered the configuration of the mold, alloy shrink rate, past quality issues and conducted simulation modeling. They recommended re-engineering the core for counter balance to avoid core float and removed a cap to create an open end, which would eliminate a weld assembly step. The casting yielded good quality, which the team validated through penetrant and radiography testing.

“Not only did we solve the quality issues, but we further eliminated a step in the Hydro-Thermal production process,” said Mitch McCaffery, Director of Sales & Marketing for SF&E. “The weld step elimination saves Hydro-Thermal 4 to 5 hours of shop floor time per piece so outside of quality, engineering this solution is what we are most proud of.”