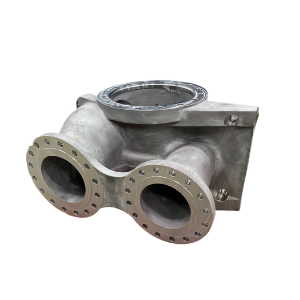

Oil refineries are complex operations with intricate, custom-made process units. Refineries that produce gasoline have at least one unit that requires a slurry pump for the process, which endures an intense environment. The catalyst slurry is so abrasive that it erodes large, industrial, heavy duty pump parts in a matter of months. Stainless Foundry & Engineering (SF&E) recently worked with a customer who had an idea on how to solve this issue – it came down to design and choice of alloy.

Turbonetics Engineering & Services is a Texas-based engineering firm specializing in the repair and upgrade of pumps, steam turbines, and gear boxes. Over the past 20-plus years, they have developed a partnership with one nearby that involves the continuous repair of their four slurry pumps, according to David Hickham, Co-owner of Turbonetics. To avoid a malfunction and prevent any unplanned downtime, the refinery removes each of three pumps (plus one spare) once they have been in service for a specified number of hours and sends them to Turbonetics for repair.