Homecoming- The Keys to Rebuilding the Domestic Supply Chain

A dramatic shift is happening in American manufacturing. This transition involves a growing number of companies reversing a six-decade trend by moving some or all their production from overseas to the United States. While this reshoring effort bodes positive change for the companies and the country, companies will need to build new supplier relationships to make this change work successfully.

For most people in this country, offshoring has been a fact during their lives. Along with automation and process improvements there has been a drop from the peak of 19.5 million manufacturing workers in 1980 to 1.3 million today.

During the past 22 years, the offshoring pace accelerated, spearheaded by China. Following its entrance to the World Trade Organization in 2001, by 2014, 3.2 million jobs exited the US, 75% of which were in manufacturing.

This sourcing change back to the US has been moving rapidly and robustly over the past two years. For example, Bloomberg states the number of new US manufacturing plants has grown by 116% over the past few years, mainly through reshoring.

A poll released in April 2023 by Forbes, Xometry, and John Zogby of 150 CEOs, found that 82% of the respondents actively embrace reshoring strategies. As a previous study found in January, this number shot up from 55% looking to move.

An Evolving Manufacturing Strategy

So, what caused this recent turnaround? First, it was the COVID pandemic. Supply chain disruptions as China drastically shut down production for months forced executives to rethink these overseas sources as the US economy grew. In addition, the factory closures in China and elsewhere contributed to inflation worldwide.

Inflation prompted the current administration to break the dependence on China for critical components. Recent legislation such as the CHIPS and Science Act and the Inflation Reduction Act are aimed at reshoring crucial computer chip and electric vehicle manufacturing on top of other programs for companies to redirect their supply chain to the United States.

Meanwhile, several other factors aligned to make manufacturing in America attractive. The Forbes poll found that significant numbers of CEOs regard the US as having sufficient manufacturing capacity to handle their supply chain.

Finally, a domestic supply chain can deliver benefits that manufacturing overseas cannot. Manufacturers are discovering the speed, flexibility, resilience, and communication offered by the domestic supply chain outweigh the lowest cost options that initially prompted these companies to source offshore.

The Reshoring Initiative® launched in 2010, takes action by helping manufacturers realize that local production, in some cases, reduces their total cost of ownership of purchased parts and tooling. It currently has 25 sponsors including major manufacturing trade associations and technology suppliers.

Doug Kurkul, CEO of the American Foundry Society, recently shared on LinkedIn that reshoring was up another 11% in the first quarter of 2023, according to the Reshoring Initiative, which he says is good news for the manufacturing economy. “AFS will continue to provide educational programs and articles encouraging OEMs and foundries to explore reshoring, and to support The Reshoring Initiative,” Kurkul wrote in a post.

If you are considering a reshoring effort, explore the Stainless Foundry & Engineering (SF&E) website for resources that will help you compare, vet, and reduce risk as you look to find your next foundry partner.

The Benefits of a Short Supply Chain

Since SF&E first opened its doors more than 75 years ago, it has differentiated itself from other foundries through its commitment to communication, responsiveness, and continuous improvement. These brand promises would be difficult to fulfill if we weren’t located within a day’s travel to every customer site. The following are top ways customers benefit from working with a domestic foundry:

Troubleshooting – SF&E has worked with many manufacturers domestically who have struggled with an overseas partner – both prior to and during COVID. Our technical expertise and proximity to our OEM customers have helped us take over failing projects, successfully produce parts, and get quality products into their hands. Learn real case histories from customers who turned an overseas challenge into a domestic success.

Staying Ahead of Industry Trends – Producing parts to spec is one thing. A working knowledge of the application they will be used for is another. Understanding how an industry is evolving puts a foundry partner in the position to ensure the work they are completing is in the best interest of its customer’s business. SF&E business leaders keep their finger on the pulse of trends, not only in pumps and valves, but in vertical industries such as food and beverage.

Quality Control – Foundry engineers, process engineers, metallurgists, welding program coordinators, and technicians at SF&E are meticulous when it comes to writing and following production control plan procedures for efficient production and quality control. Our work for the federal government, US Navy, and the Department of Defense is a testament to this.

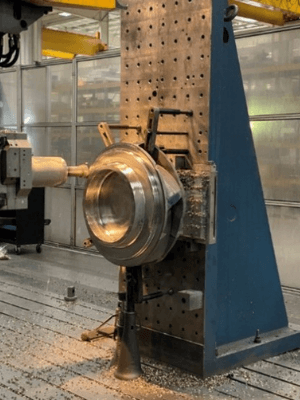

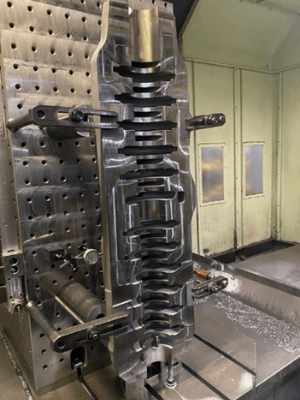

Strength in Partnerships – Approved suppliers for SF&E are typically selected because they can serve as an extension of our in-house team by supplementing service offerings and handling overflow. They need to be available, reliable, and hold the same standards of quality and lead times that we hold to ourselves. Our preferred partnership with Strohwig Industries, for example, is a two-way street where we leverage their state-of-the-art machining capabilities to serve our customers and they leverage our ability to produce high-quality castings to serve theirs.

How to Select a Domestic Foundry

There are many reasons why original equipment manufacturers (OEMs) question their relationship with an existing foundry partner – both domestic and abroad – from inconsistent quality to ineffective communication. Although there is typically only one reason, they continue to work with the foundry anyway – the risk of uncertainty.

SF&E’s goal is to create long-term partnerships with our OEM customers. The following are top ways to reduce risk when selecting a new foundry partner and conduct a successful migration of patterns once the decision is made:

Capabilities – Foundries will need to compare the chemistry and mechanical properties of your alloy when assessing if they can take your project on. Ask the foundry if they are used to making something similar – this lowers the risk of transferring your part over. If you can, get more information such as whether similar alloys have given them problems and if they were able to identify the source and correct it. SF&E has dedicated an entire section of our website to metallurgy to help OEMs understand the experience we have with pouring over 250 alloys, including an interactive casting alloy selector and alloy comparison tool.

Quality Assurance – Thorough testing is imperative to ensure castings not only meet customer and industry standards, but they have the structural integrity to perform throughout their expected service life. SF&E serves a broad set of industries including chemical, petrochemical, nuclear, pulp and paper, pharmaceutical, food and dairy, metering, and military markets with corrosion-resistant, high heat, and wear resistant steel, stainless steel and high alloy parts. Our quality assurance, open communication channels, collaborative problem-solving, and consistency have led to effective production partnerships with customers such as Hydro-Thermal, Schutte & Koerting, and Fristam Pumps.

Capital Investment – The price, service, and long-term viability of a foundry are all top concerns for OEMs looking to take the leap to a new foundry. Like many labor-intensive industries, foundries need to maintain a strong workforce with an eye toward innovation. The number of patterns we produce at SF&E and the customers we serve has increased substantially over the last decade, allowing us to continue to invest and grow our business. SF&E’s investment in a high specification cell helped with high spec production efficiency, cost reduction for customers, and an opportunity for employee development.

A Clear Picture – Even if a foundry checks all the boxes when it comes to capabilities, quality assurance, and continued investment, it is important for OEMs to be able to get a clear picture of what the partnership will be like, such as how the foundry plans to guide you through the patten and tool transition. Checkout our helpful guide to the 4 Critical Questions to Ask Before Working with a New Foundry.

The rewards outweigh the risks of bringing work closer to home, such as better communication and control. In the foundry industry, proximity does have its value.

If you are ready to move manufacturing from overseas and are looking for a domestic foundry partner committed to quality, contact SF&E today at sales@stainlessfoundry.com.